Installation

Step by Step GuidesTechno Guides

Laying Membrane Edge Trims Gutter Trim External Edge Corner Wall Trim Flashing Under Tiles Onto Tiles Wall Trim Flashing External Corner (Skylight / Upstand) Internal Corner Pipeseal Seam / Join Rainwater Outlet Horizontal Rainwater OutletLineflex Guides

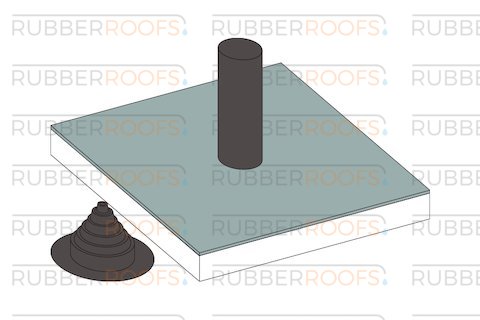

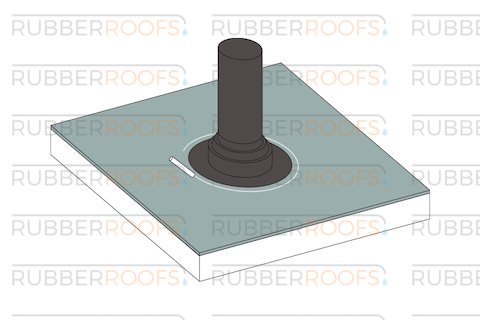

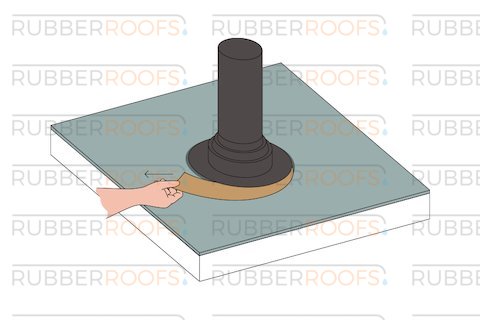

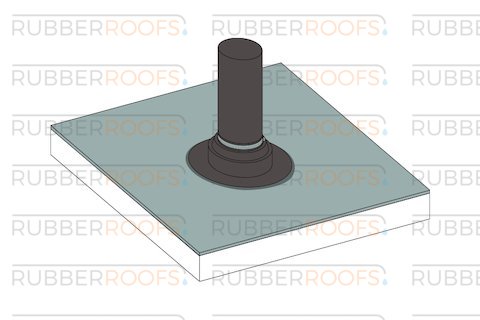

Lineflex Heat Weld Laying Lineflex Laying Lineflex With Spray Adhesive Laying Lineflex With Mechanical Fixings Edge Trim Gutter Trim External Edge Corner Under Tiles Onto Tiles External Corner Internal Corner Pipe Seal Felt Join Butt Join Rainwater Outlet Horizontal Rainwater OutletPipeseal Download PDF

Step by step guide on installing a pipeseal to your next EPDM Roofing project.